An Explanation of Magnetic Separation Technology

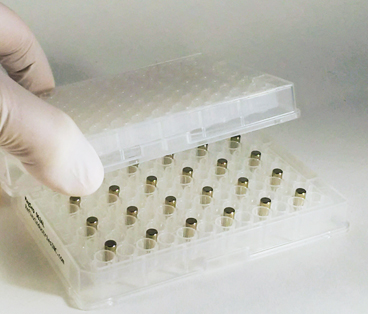

Magnetic Separation Racks for 96-well MicroPlates using ParaMagnetic Particles (PMPs)

We provide inexpensive, lightweight and sturdy Magnetic Separation Racks for 96 well microplates.

When using Paramagnetic Particles (PMPs) instead of coated flat bottom microplates,

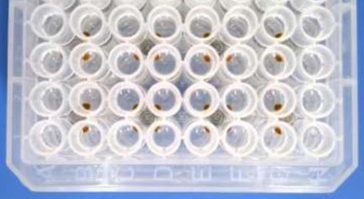

round bottom wells are best for magnetic separation of assay and washing fluids from the PMPs using vacuum aspiration.

Polypropylene plates are preferred over polystyrene microplates because they are rugged enough to be cleaned and reused.

Some vendors recommend decantation,

but our experience has shown significant loss of PMPs due to the "slapping" that is necessary to remove the fluid.

Vacuum aspiration is preferred, but still some PMPs may be lost if meticulous technique is not practiced.

Our bottom magnetic separation racks are catalog number 9624L, and include 10 round bottom polypropylene microplates.

We use and supply Greiner model 650201 MicroPlates.

The round bottoms of the wells provide space for the magnets to go in between four adjacent wells.

The PMPs are pulled to the sides of the wells, off the bottom to allow for cleaner vacuum aspiration.

The magnets used in the separation racks are N52 neodymium cylinders, the strongest currently available.

Separation takes place in seconds.

Each of the magnetic separation racks supplied come in a metal container for safe use and storage.

catalog number 9624L - Our Bottom Magnetic Separation Rack for MicroPlates can be purchased here.